is the ideal solution for belt-driven ventilation systems. The proof is in the numbers.

is the ideal solution for belt-driven ventilation systems. The proof is in the numbers.

Case Study: Large Bakery Production Facility

Application: Belt-driven Exhaust Fans

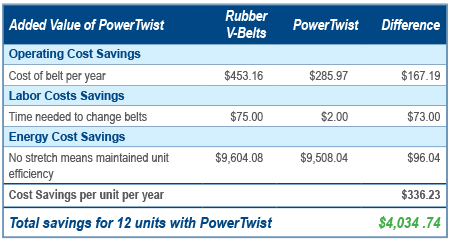

Annual Cost Savings: $4,035

- 83% reduced operating costs

- 97% reduced labor costs

- 6x longer belt life than rubber

- Increased energy efficiency

- Eliminated emergency purchase trips

|

| Problem: |

|

Calculated Cost Savings |

- Rubber V-belts required 30 minutes to change.

- Belt replacement was performed every 2 months.

- Belts stretched, lost efficiency and required retensioning.

|

|

|

| Solution: PowerTwist V-belts |

|

- Inventory was reduced to a few boxes of PowerTwist and belts are made

to the required length on-site. The right amount of inventory is on hand at

all times, thus eliminating excess capital tied up in spares.

- Belt life was extended to 12+ months.

- PowerTwist does not stretch and does not require retensioning after

initial run in.

|

|

<Back to List

Learn more about PowerTwist high performance belting

Learn more about other Climate Control solutions from Fenner Drives

Find out how you can save with PowerTwist.

Complete the form below or click to find your local Fenner Drives rep