|

Belting is the ideal solution for fast installation and reduced downtime on belt-driven conveyors.

|

Case Study: Large European Furniture Manufacturer

Application: Belt-driven Kitchen Worktop Conveyors

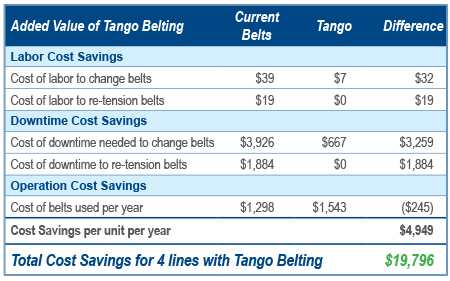

Annual Cost Savings: $19,796

- 88% reduced labor costs

- 89% reduced downtime costs

- 3x faster belt installation time

- $5k savings per unit

|

| Problem: |

|

Calculated Cost Savings |

- Rubber belts elongate and require re-tensioning. Lack of maintained tension prevented Worktops from conveying properly.

- Rubber belts leave a dust accumulation under the pulleys.

- The installation process took 30 minutes to complete.

|

|

|

| Solution: PowerTwist Move Belting |

- PT Move maintains the proper tension, providing a maintenance free solution.

- PT Move dropped right in existing pulleys and produces virtually no dust.

- PT Move can be installed in 10 minutes or less.

|

|

<Back to List

Learn more about PowerTwist Move Conveyor Belting

Learn more about other industry specific solutions from Fenner Drives

Find out how you can save with PowerTwist Move.

Complete the form below or click to find your local Fenner Drives rep