|

Friction Top is the ideal solution for longer belt life and reduced downtime on belt-driven conveyors.

|

Case Study: Global Building Materials Manufacturer

Application: Belt-driven Ceiling Tile Conveyors

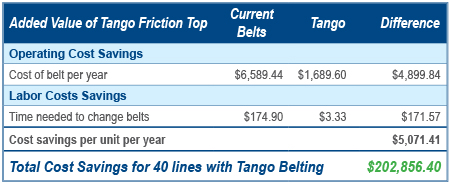

Annual Cost Savings: $202,856

- 92% reduced operating costs

- 98% reduced labor costs

- 12x longer belt life

- 4x faster belt installation time

- $5k savings per unit

|

| Problem: |

|

Calculated Cost Savings |

- Current belts only lasted 1 month.

- High cost of labor necessary to weld and install new urethane belts every month.

- High coefficient of friction needed to grip the ceiling tiles.

|

|

|

| Solution: PowerTwist Move Friction Top Belting |

|

- Belt life was extended to 12 months.

- Tango link belting is made to length by hand with no welding and no curing time involved – installation time was reduced by 75%.

- PowerTwist Move Friction Top has a top layer of 85A polyurethane incorporated into each link, which offers a higher coefficient of friction for added conveying grip.

|

|

<Back to List

Learn more about Tango specialty conveyor belting

Learn more about other Tile and Shingle Manufacturing solutions from Fenner Drives

Find out how you can save with PowerTwist Move.

Complete the form below or click to find your local Fenner Drives rep