is the ideal solution for minimized downtime and longer belt life in power transmission applications.

is the ideal solution for minimized downtime and longer belt life in power transmission applications.

Case Study: International Glass Manufacturing Company

Application: Glass Conveying Ovens

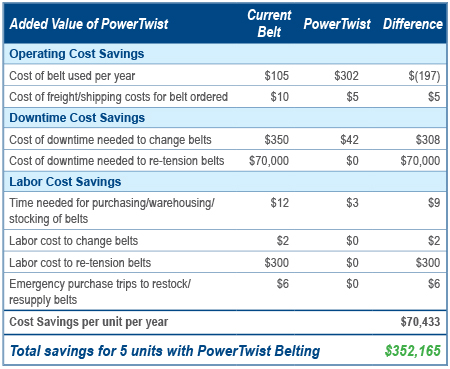

Annual Cost Savings: $352,165

- 99.9% savings with reduced downtime

- 99% reduced labor costs due to quicker changeover time

- 6x longer belt life

- Required labor reduced from 5 technicians to 1

|

| Problem: |

|

Calculated Cost Savings |

- Five people required to replace the existing urethane belts.

- Replacement time for the urethane belt was 4.3 hours.

- Total annual lost production time: 26 hours due to unscheduled machine downtime.

- Average belt life was 52 production days.

|

|

|

| Solution: PowerTwist V-belts |

|

- Using PowerTwist, a single person can now replace the belts.

- Replacement time for PowerTwist is just nine minutes.

- Total annual lost production time: reduced to nine minutes of unscheduled downtime.

- PowerTwist lasted 312 production days without being replaced.

|

|

<Back to List

Learn more about PowerTwist high performance V and Round belting

Learn more about other Glass Manufacturing solutions from Fenner Drives

Find out how you can save with PowerTwist.

Complete the form below or click to find your local Fenner Drives rep