|

is the ideal solution for increased quality, longer belt life, and reduced downtime on glass conveyors.

|

Case Study: Global Automotive Glass Manufacturer

Application: Belt-driven Windshield Production Conveyors

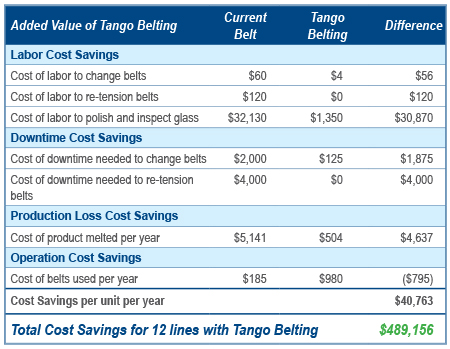

Annual Cost Savings: $489,156

- 98% reduced downtime

- 96% reduced labor costs

- 90% savings from reduced product losses

- Eliminates belt re-tension time

|

| Problem: |

|

Calculated Cost Savings |

- Customer utilized urethane belts, which were marking the glass.

- Labor hours: Customer had a person dedicated to removing and cleaning the markings/scratches. Process consist of polishing, washing and re-inspecting each of the damaged pieces.

- Downtime associated with frequent urethane belt changes and re-tensioning and welding.

|

|

|

| Solution: PowerTwist Move Belting |

|

- By utilizing PT Move Belting, the customer reduced labor by 96% for that unit.

- Improved product losses by considerably reducing waste.

- Improved quality of the finished product.

- Reduced downtime by 98% due to fewer belt changes.

|

|

<Back to List

Learn more about PowerTwist Move Conveyor Belting

Learn more about other Glass Manufacturing solutions from Fenner Drives

Find out how you can save with PowerTwist Move.

Complete the form below or click to find your local Fenner Drives rep