The Performance You Need

Most standard bearings are over-specified for their applications, wasting money and space in your design.

National Bearings’ customized thrust washers, ball thrust retainers, needle thrust retainers, and mounted bearings give you the performance you need. Saving you money and reducing space requirements.

In many applications, composite products match the performance of metal, slashing tooling lead time from months to weeks. Improving working life and reducing maintenance requirements. Plus, housings and retainers are resistant to corrosion.

So you get exactly the performance you need, from a custom part designed for your application.

Download the National Bearings Flyer

| THRUST WASHERS AND PRECISION SPACERS |

Thrust washers differ from standard washers or spacers because they must carry a bearing load and not wear out over time. Also called thrust bearings, plane bearings, wear rings, thrust ring, spacers, and shims, we offer thrust washers in hundreds of sizes and shapes including flat thrust, keyed thrust, and tabbed thrust washers.

Our custom stamped thrust washers are used by OEMs around the world in diverse applications from power tools to gearboxes and from furniture to automobiles.

For more demanding applications, we also manufacture high precision ground thrust washers and spacers.

RESOURCES:

Ball thrust retainers are used in applications where a full complement of balls is not needed to support the load. Also called thrust bearing cages, they separate the balls, usually requiring less space and cost less than a comparable standard thrust bearing. Retainers are often paired with thrust washers as a custom thrust bearing.

Most applications don’t need the capacity that standard bearings are designed to handle. A retainer can be designed with the correct number of balls to match the application load.

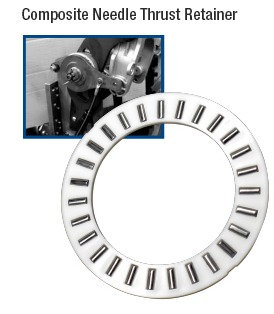

| COMPOSITE NEEDLE THRUST RETAINER |

Needle thrust retainers are used in products where a high load capacity is required in a small space. They are typically used with one or more thrust washers. While metal needle thrust retainers are available in standard sizes, composite needle thrust retainers are much more customizable than metal needle thrust retainers.

And they can be designed and built in less time. Lead times drop from months to weeks. And tooling costs less as well.

RESOURCES:

| COMPOSITE MOUNTED BEARINGS |

In difficult operating environments, National Bearings mounted bearings provide superior performance to standard mounted bearings. Their composite housings weigh less and offer better corrosion resistance than cast or steel housings. When combined with the correct bearing insert, our composite mounted bearings deliver outstanding durability and reliability.

In difficult operating environments, National Bearings mounted bearings provide superior performance to standard mounted bearings. Their composite housings weigh less and offer better corrosion resistance than cast or steel housings. When combined with the correct bearing insert, our composite mounted bearings deliver outstanding durability and reliability.

We offer composite pillow-block and flange-mounted bearings in a wide range of standard sizes and styles. Ball-bearing inserts and spherical-plane-bearing inserts are available in a range of materials to meet any requirement.

In extreme operating environments with oscillating or low speed loads, such as carwashes or quarries, our new National Bearings composite pillow block with Fenlon bearing insert can perform long after a standard ball bearing insert has completely failed. Its Fenlon™ liner provides solid lubrication, eliminating the need for greasing and reducing the frequency of planned maintenance. And its stainless-steel inner and outer bearing race and composite housing make the bearing corrosion-resistant, allowing it to operate even when exposed to water, chemicals, fuels, oils, and other contaminants.

The Fenlon liner was developed through the world-class materials science expertise of our Hi-Tech Coated Fabrics group.

And they can be designed and built in less time. Lead times drop from months to weeks. And tooling costs less as well.

RESOURCES:

| STAMPED BEARINGS - RADIAL AND ANGULAR CONTACT |

In many consumer product applications that experience light loads and a limited lifetime use, custom metal stamped bearings can provide a more cost-effective solution than a standard bearing. Stamped radial and angular contact bearings can meet limited space requirements and integrate features like mounting brackets to reduce the number of components in a product. Stamped bearings are often ideal when the lifecycle requirements of a product are measured in hours of use rather than millions of cycles.

And they can be designed and built in less time. Lead times drop from months to weeks. And tooling costs less as well.

Fenner Custom Advantage

With any of our National Bearings products, you’re backed by the Fenner Drives custom experience. We’re with you all the way from concept and product design, prototyping and pilot production. To quality documentation and support, inventory management and packaging/kitting. Everything you need to support your design, development, and production processes.

Start the collaboration process today