is the ideal solution for minimized downtime and longer belt life in power transmission applications.

is the ideal solution for minimized downtime and longer belt life in power transmission applications.

Case Study: National Cold Forge Manufacturing Company

Application: Mechanical Stamping Press

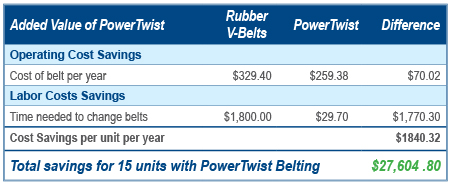

Annual Cost Savings: $27,604

- 98% reduced labor costs

- 21% reduced operating costs

- 10x faster installation time

- Virtually eliminated lost production costs

|

| Problem: |

|

Calculated Cost Savings |

- There are 15 Stamping presses using rubber V-belts with inconsistent life

expectancy and often premature failure.

- Belt replacement took two full days, requiring extensive disassembly

of the machine.

- Expensive outside contractors were needed for rigging, hoists, and

machine repair.

|

|

|

| Solution: PowerTwist V-belts |

|

- PowerTwist was fitted in place, around existing equipment – no disassembly

of the presses was required.

- Installation time was reduced by 90% and only takes 90 minutes to complete.

- The work was quickly performed by in-house employees, reducing downtime

to near zero and eliminating the need for outside contractors.

|

|

<Back to List

Learn more about PowerTwist high performance V and Round belting

Learn more about PowerTwist high performance Wedge belting

Find out how you can save with PowerTwist.

Complete the form below or click to find your local Fenner Drives rep