Return Rollers will provide reduced downtime and longer belt life on wallboard forming lines.

Return Rollers will provide reduced downtime and longer belt life on wallboard forming lines.

Case Study: Global Gypsum Board Manufacturing Company

Application: Gypsum Wallboard (Drywall) Forming Line

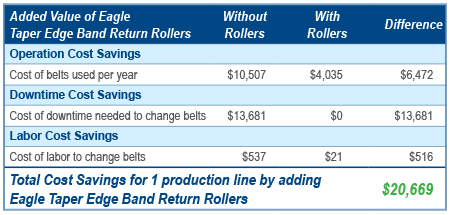

Annual Cost Savings: $20,669

- 89% in reduced operation costs

- 96% in reduced labor costs

- Eliminated downtime costs

- Up to 6x longer belt life

- Flexible installation – mounts in various positions

|

| Problem: |

|

Calculated Cost Savings |

- Taper Edge Bands were in direct contact with metal components on the forming

line, which caused increased wear on the belts, thus reducing life significantly.

- Belts were changed every month on the right hand side and every other month

on the left hand side.

|

|

|

| Solution: Eagle Taper Edge Band Return Rollers |

|

- Eagle Taper Edge Band Return Rollers reduced contact with the metal frame components below the forming conveyor, significantly reducing how quickly

the belts wear.

- Belts are now only changed twice a year.

|

|

<Back to List

Learn more about Eagle Taper Edge Band

Learn more about other Gypsum Wallboard Manufacturing solutions from Fenner Drives

Find out how you can save with Eagle Taper Edge Band.

Complete the form below or click to find your local Fenner Drives rep