is the ideal solution for minimized maintenance and longer belt life in wood processing applications.

is the ideal solution for minimized maintenance and longer belt life in wood processing applications.

Case Study: Large European Forestry Company

Application: Belt-driven Timber Debarker

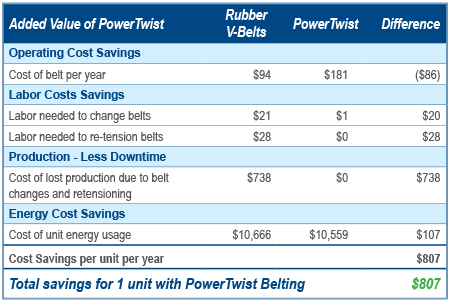

Annual Cost Savings: $807

- 99% reduced labor costs

- Virtually eliminated expensive downtime costs

- Increased energy efficiency

- Greatly reduced belt installation time

- Longer belt life in harsh operating conditions

|

| Problem: |

|

Calculated Cost Savings |

- Rubber belts elongate and require re-tensioning.

- Elongated belts slip causing energy efficiency to drop.

- The Debarker is critical to keep the production line moving,

meaning downtime is very costly.

|

|

|

| Solution: PowerTwist Wedge Belts |

|

- PowerTwist does not elongate, providing a maintenance free solution.

- No stretch means the belt maintains peak efficiency.

- Downtime is reduced to nearly zero.

|

|

<Back to List

Learn more about other Wood Processing Solutions

Learn more about PowerTwist high performance Wedge belting

Find out how you can save with PowerTwist.

Complete the form below or click to find your local Fenner Drives rep