Roller Drive is the ideal solution for minimized downtime on belt-driven live roller conveyor systems.

Roller Drive is the ideal solution for minimized downtime on belt-driven live roller conveyor systems.

Case Study: Global Food Manufacturing and Processing Company

Application: Powered Roller Curves

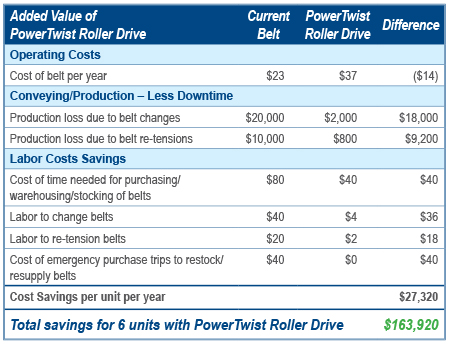

Annual Cost Savings: $163,920

- 91% savings with reduced downtime

- 74% reduced labor costs due to quicker installation time

- 3x longer belt life

- 3x faster installation time

|

| Problem: |

|

Calculated Cost Savings |

- Current belts required replacing every 12 months due to wear and fatigue.

- Belt replacement required dismantling the idler pulley system, causing up to

90 minutes of expensive downtime.

|

|

|

| Solution: PowerTwist Roller Drive |

|

- Belt life now exceeds 3 years. The combination of high strength and low

elongation under load resulted in increased V-belt longevity and durability.

- Easier installation without dismantling idler pulley systems. Belt replacement

time was cut in third to under 30 minutes.

|

|

<Back to List

Click here for more info or to purchase PowerTwist Roller Drive belting

Click here to learn more about other Distribution Center solutions from Fenner Drives

Find out how you can save with PowerTwist Roller Drive.

Complete the form below or click to find your local Fenner Drives rep